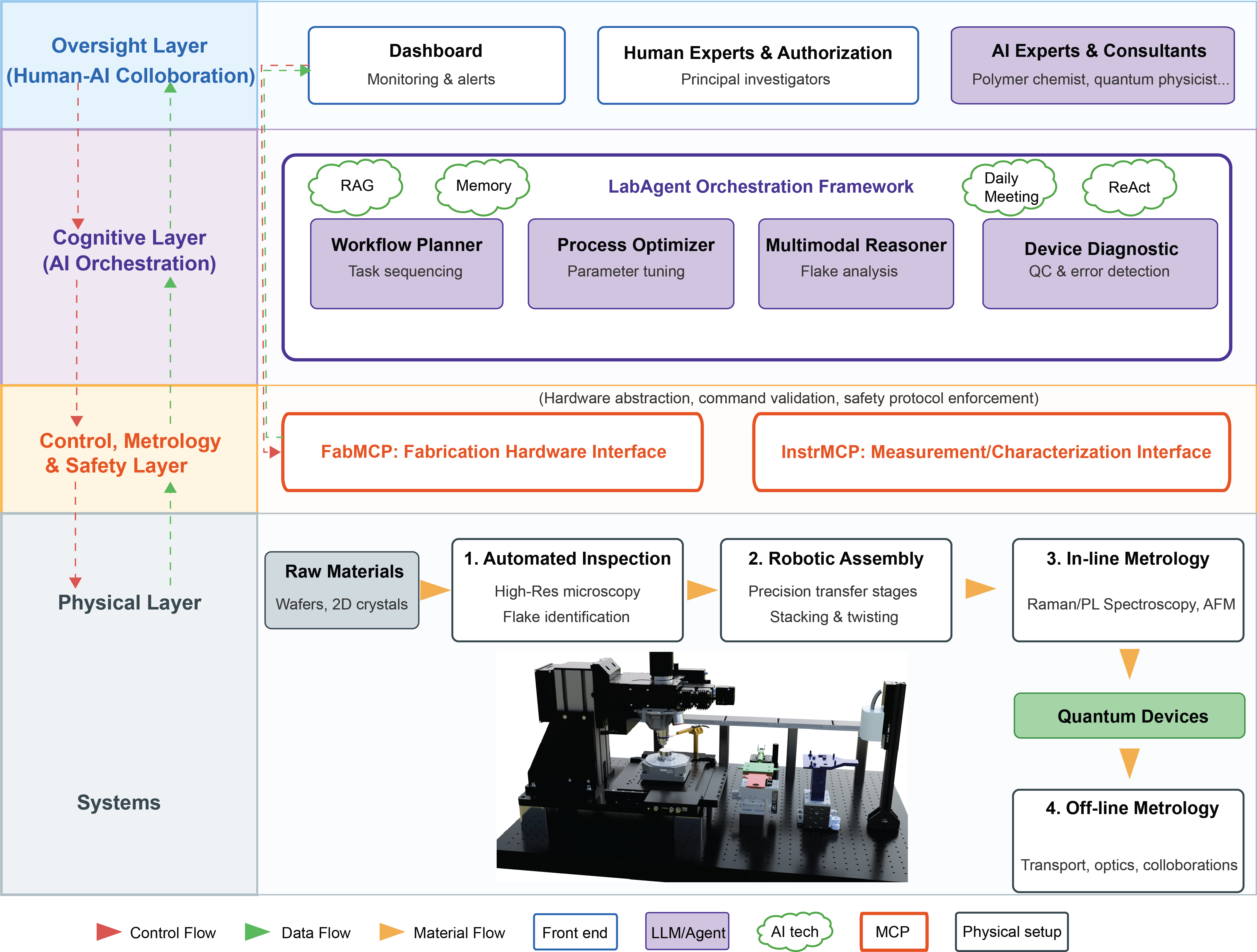

System Architecture

AIM2D integrates four key layers and three fabrication stages for end-to-end autonomous manufacturing

Four Key Layers

Each layer serves a distinct purpose in the autonomous ecosystem, working together to enable safe, intelligent, and efficient device fabrication.

Oversight Layer

Human-AI collaboration ensuring alignment with research goals. PIs set high-level scientific objectives, with monitoring dashboards and authorization for critical steps.

Read more in proposal →Cognitive Layer: LabAgent Framework

AI orchestrator for decision-making and planning. Features workflow planning via RAG, process optimization, multimodal reasoning, and device diagnostics using ReAct framework.

Read more in proposal →Control & Safety Layer

Standardized interface for hardware using Model Context Protocol. Validates commands against safety rules before execution, with separate modules for fabrication and instrumentation.

Read more in proposal →Physical Layer: Hardware

Robotic systems handling material flow from preparation through stacking to characterization. Features modular tool-changer and motorized stages for precision alignment.

Read more in proposal →Three Fabrication Stages

The physical layer operates in three main stages, moving materials from raw form to completed, characterized devices.

Material Preparation

Automated sourcing via CVD films or multi-roller exfoliation. AI vision inspects and selects highest-quality flakes for device assembly.

Heterostructure Stacking

Robotic arm guided by AI performs precise assembly. Motorized heated stage enables automated cutting, sub-micron positioning, and exact twist-angle alignment.

Characterization

Integrated AFM and Raman spectrometer analyze finished structures. Mid-assembly quality checks possible without losing alignment.

System Architecture Diagram

Complete overview of the four-layer architecture and physical system integration

Innovative Design Elements

What sets AIM2D apart from previous robotic fabrication systems

- •Modular Tool-Changer: Supports multiple end-effectors including chip-tray gripper, stamp manipulator, and silicon-chip gripper for seamless task switching.

- •AI-Driven Tool Selection: Intelligent reasoning to select optimal tools and strategies for each fabrication step.

- •Mid-Assembly Quality Checks: Perform quality verification without losing alignment, enabling real-time corrections.

- •Continuous Integration: Freely programmable, semi-modular platform designed for continuous addition of new functionalities.